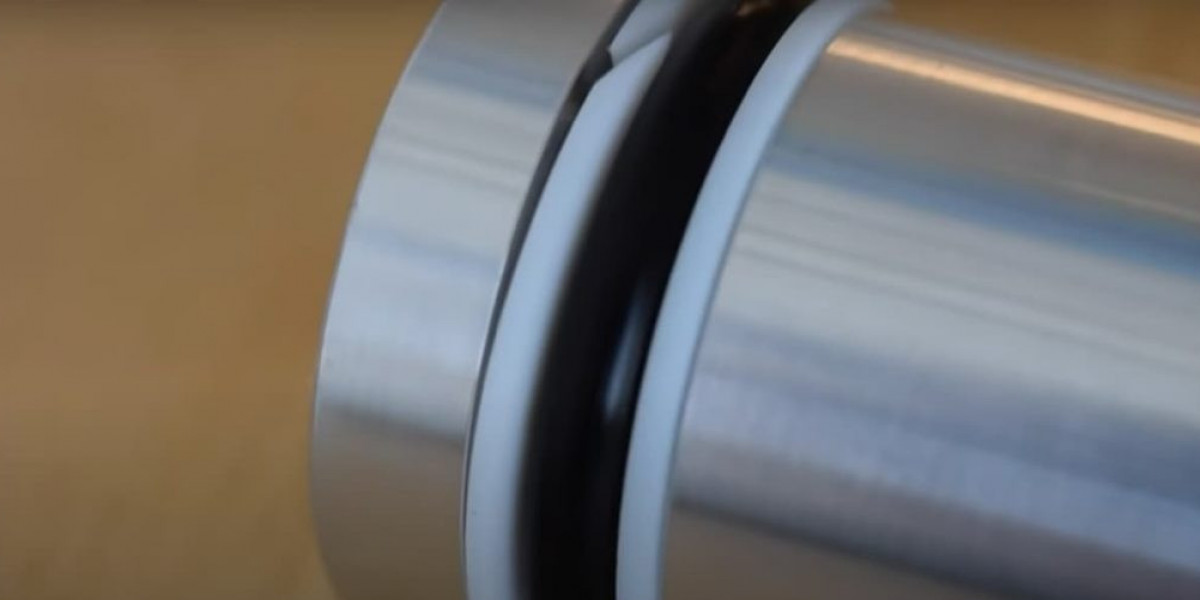

O-rings are circular seals that prevent gas and liquid from passing through an opening in equipment. Over time, they will wear out and need to be replaced. Whether you are replacing an old one or designing an entirely new system, correctly determining the right size can save time and money in the long run. It is important to get it right the first time. Using the wrong one can result in a leaky, uncomfortable, or unreliable seal. Getting the size right requires taking a few key measurements accurately.

Measuring O-rings involves two separate, critical measurements – the inside diameter and the cross section. In order to take these measurements, the o-ring should be placed on a clean and level surface. The inside diameter is measured from the inner edge of one ring to the inner edge of another. This is often abbreviated as the ID. The cross-section is measured from the o-ring’s thickness or width and is known as the CS.

Both measurements can be taken with a caliper, vernier or a precision measuring instrument. Using these tools, the o-ring can be positioned so that the smallest cross-section is at the point of contact with the groove in which it will fit. It is important that the groove dimensions are accurate and have been matched with the o-ring’s dimensions to avoid misalignment.

Once the o-ring is positioned, the measurements can be taken with these tools or a digital caliper. It is best to use a digital caliper for both measurement purposes and to ensure that the o-ring is seated properly. A digital caliper will provide more precise results and will allow you to adjust the o-ring in case it is too loose or tight.

Having the correct o-ring in place will ensure that fluids, dirt, dust and grit are prevented from entering the system. It will also ensure that the o-ring does not wear out prematurely due to being too big or being overstretched during installation and usage.

While there are many factors to consider when sizing an o-ring, it is relatively easy to do and does not require much practice. Knowing the proper steps to take will ensure that you are ordering a replacement o-ring with the correct dimensions and thus creating a leak-proof seal in your application.

Metric and standard sizes are available. Generally, if an o-ring’s dimensions match a standard AS568 (Aerospace Standard) size, it will be a standard sized o-ring. However, metric sizes are becoming increasingly common in the US and internationally.

If you are unsure about which size is correct for your application, please do not hesitate to contact our customer service team. Our knowledgeable staff will be happy to assist you. In addition, a complete library of o-ring size charts can be found online to help you determine the correct O-ring for your application. We offer a wide variety of standard and metric o-rings made from top-quality fluoroelastomers like Buna, Viton and silicone.