According to Stratview Research, the unidirectional tapes market is projected to grow at a healthy CAGR over the next five years to reach an estimated value of US$ 3.1 billion in 2026.

In the realm of advanced composite materials, unidirectional tapes are emerging as a game-changer, offering unique properties and capabilities that are revolutionizing industries ranging from aerospace and automotive to construction and sports equipment. As manufacturers seek lightweight, durable, and high-performance materials, the unidirectional tapes market presents a wealth of opportunities for innovation and growth.

Unraveling the Potential of Unidirectional Tapes

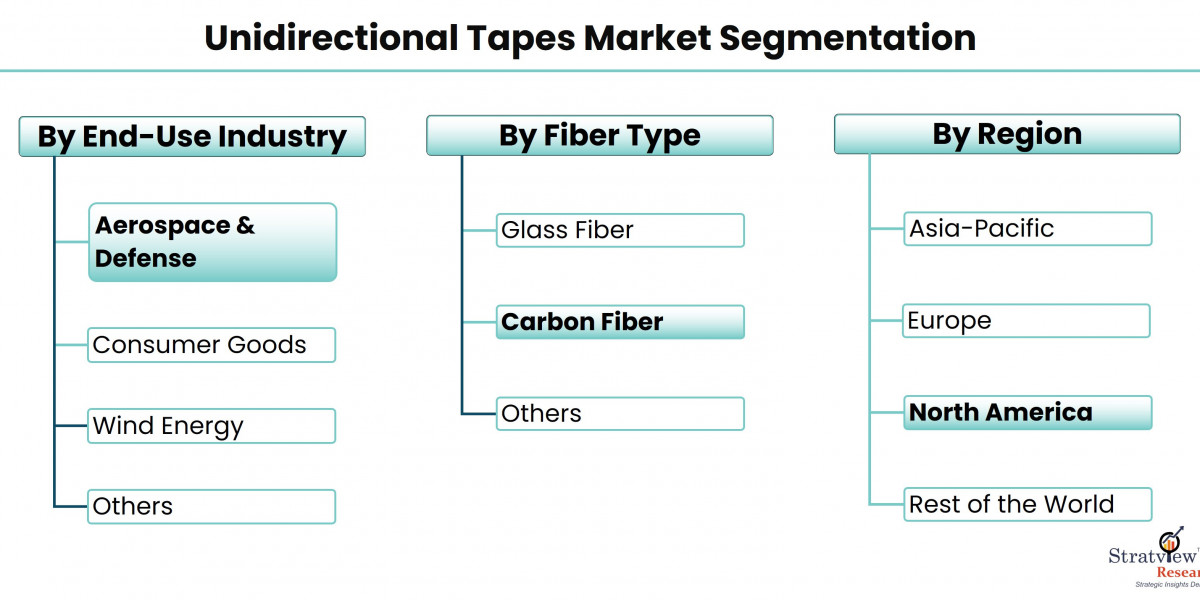

Unidirectional tapes are composed of high-strength fibers, such as carbon, glass, or aramid, aligned in a single direction and held together by a polymer matrix. This unique structure provides exceptional strength, stiffness, and fatigue resistance, making unidirectional tapes ideal for applications where lightweight and high-performance materials are essential.

Driving Factors Behind Market Growth

Demand for Lightweight Materials: With increasing emphasis on fuel efficiency, sustainability, and performance, industries such as aerospace, automotive, and wind energy are turning to lightweight materials like unidirectional tapes to reduce weight without compromising strength or durability.

Advancements in Manufacturing Technologies: Innovations in manufacturing processes, such as automated tape laying (ATL) and automated fiber placement (AFP), have made it possible to produce complex composite structures with greater precision, efficiency, and cost-effectiveness, driving the adoption of unidirectional tapes in various industries.

Growing Applications Across Industries: Unidirectional tapes are finding applications across a wide range of industries, including aerospace, automotive, marine, sporting goods, and infrastructure. From aircraft fuselages and automotive chassis to wind turbine blades and sporting equipment, the versatility of unidirectional tapes is fueling their adoption in diverse applications.

Opportunities for Innovation and Collaboration

The unidirectional tapes market presents numerous opportunities for innovation and collaboration among stakeholders across the value chain. From material suppliers and manufacturers to end-users and research institutions, collaboration is essential for driving advancements in materials, processes, and applications.

Material Suppliers: Suppliers of high-performance fibers and polymer matrices play a crucial role in the unidirectional tapes market by providing the raw materials needed for composite production. Continued innovation in fiber and resin technology, such as the development of lightweight and environmentally friendly materials, will further enhance the performance and sustainability of unidirectional tapes.

Manufacturers: Manufacturers of unidirectional tapes and composite components are leveraging advancements in manufacturing technologies to improve efficiency, quality, and scalability. By investing in state-of-the-art equipment and process optimization, manufacturers can meet the growing demand for advanced composite materials while reducing production costs and lead times.

End-Users: End-users in industries such as aerospace, automotive, and sports equipment are driving demand for lightweight and high-performance materials like unidirectional tapes. By collaborating with material suppliers and manufacturers, end-users can co-develop innovative solutions tailored to their specific application requirements, leading to enhanced performance, efficiency, and competitiveness.

Conclusion

The unidirectional tapes market offers exciting opportunities for innovation and growth in the field of advanced composite materials. With their unique combination of strength, stiffness, and lightweight properties, unidirectional tapes are poised to play a significant role in shaping the future of industries ranging from aerospace and automotive to marine and infrastructure.

By leveraging advancements in materials, manufacturing technologies, and collaborative partnerships, stakeholders across the value chain can unlock new possibilities for product development, cost reduction, and market expansion. As we continue to explore the opportunities presented by unidirectional tapes, we can expect to see further advancements in materials science, manufacturing processes, and end-user applications, driving continued growth and innovation in the dynamic and evolving world of advanced composite materials.