When it comes to industrial metalworking and fabrication, bending equipment plays a crucial role in ensuring precision and efficiency. As one of the leading manufacturers, ACCURL specializes in offering state-of-the-art solutions for your bending needs. Whether you're handling sheet metal, tubes, or specialized components, the right bending equipment can transform your production capabilities.

What is Bending Equipment?

Bending equipment encompasses a wide range of machinery designed to shape metal and other materials by applying force to create precise angles, curves, or folds. These machines are critical for industries like automotive, construction, aerospace, and manufacturing, where precision and durability are paramount.

Common Types of Bending Equipment

Press Brakes

Press brakes are the cornerstone of metal bending. These machines use a combination of force and tooling to create bends with unmatched precision. Available in hydraulic, mechanical, and electric models, press brakes are highly versatile.Hydraulic Press Brakes: Known for their consistent force and flexibility in handling thicker materials.

Electric Press Brakes: Offer precision and energy efficiency, making them ideal for high-speed production lines.

Tube Bending Machines

Designed specifically for bending pipes and tubes, these machines ensure smooth, distortion-free curves.CNC Tube Benders: Perfect for complex designs, offering programmable precision for multiple bends.

Rotary Draw Benders: Ideal for tight radius bends and consistent repeatability.

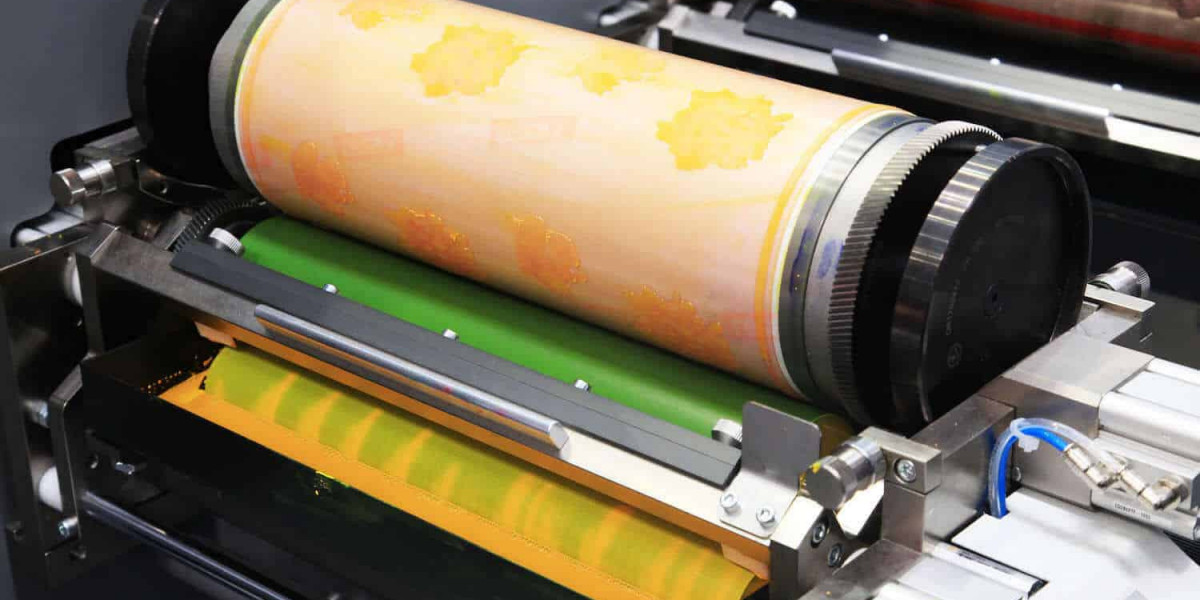

Roll Benders

Roll bending machines use a set of rollers to form large-radius bends, typically for structural components or cylindrical items.Panel Benders

Panel benders are specialized for bending sheet metal panels in bulk, commonly used in the appliance and cabinetry industries.

Key Features to Look for in High-Quality Bending Equipment

Choosing the right bending equipment can drastically impact your operational efficiency and product quality. Here are the essential features to consider:

1. Precision and Accuracy

Advanced bending equipment like CNC machines ensures every bend meets exact specifications, reducing material waste and rework.

2. Durability

Industrial-grade materials and components ensure machines can handle high volumes without compromising performance.

3. Programmability

CNC technology allows operators to program complex bends, enabling repeatable and consistent results across production runs.

4. Energy Efficiency

Modern machines incorporate energy-saving technologies, reducing operational costs without sacrificing performance.

5. Safety Features

Integrated safety systems, such as light curtains and emergency stops, ensure operator protection during operations.

Applications of Bending Equipment

Bending equipment is essential in various industries, catering to both standard and custom manufacturing needs.

Automotive Industry

Chassis Fabrication: High-precision bending for complex automotive frames.

Exhaust Systems: Smooth bends ensure optimal airflow and performance.

Aerospace

Aircraft Components: Lightweight yet durable metal parts are formed using precision bending equipment.

Structural Integrity: Reliable bends enhance the safety and performance of aircraft.

Construction

Steel Beams and Frames: Roll benders create curved components for architectural structures.

Reinforcements: Tubular bending equipment is used for rebar and pipe reinforcements.

Furniture Manufacturing

Ergonomic Designs: Tubular bends allow for sleek and functional furniture designs.

Sheet Metal Forming: Panel benders craft durable and aesthetic panels.

Advanced Technology in Bending Equipment

The advent of Industry 4.0 has revolutionized bending equipment, introducing cutting-edge technology to streamline production.

1. CNC Integration

CNC-controlled machines deliver unparalleled precision and reduce human error. Programmable functions also allow for seamless switching between different bending operations.

2. Automation and Robotics

Fully automated bending systems minimize manual intervention, speeding up production and increasing accuracy. Robotic arms can handle material feeding, improving workflow efficiency.

3. IoT and Real-Time Monitoring

IoT-enabled bending equipment provides real-time data on machine performance, ensuring predictive maintenance and minimizing downtime.

4. Adaptive Bending Technology

Modern machines can automatically adjust to material thickness and properties, reducing setup time and enhancing flexibility.

Maintenance and Care of Bending Equipment

Proper maintenance ensures the longevity and optimal performance of your bending equipment.

Routine Inspections

Check for wear and tear on tooling and mechanical parts.

Regularly inspect hydraulic systems for leaks or pressure inconsistencies.

Lubrication

Keep moving parts well-lubricated to prevent friction and overheating.

Use manufacturer-recommended lubricants for best results.

Software Updates

Keep CNC and automated systems updated to leverage the latest features and security patches.

Operator Training

Ensure operators are trained on proper machine usage and maintenance practices to avoid misuse and damage.

Choosing ACCURL for Your Bending Equipment Needs

ACCURL stands out in the bending equipment market by combining innovation, quality, and customer-focused solutions. With a comprehensive range of machines tailored to diverse industrial requirements, we ensure our clients achieve the best results. From high-performance press brakes to advanced tube benders, our equipment is designed to handle the toughest challenges.

Why ACCURL?

Unmatched Quality: Built with industrial-grade materials for long-lasting performance.

Custom Solutions: We offer tailored configurations to meet specific project needs.

Global Support: With a dedicated customer service team, we provide prompt assistance worldwide.

Sustainability: Our machines are designed with energy efficiency in mind, reducing operational costs and environmental impact.

Conclusion

Investing in the right bending equipment is essential for optimizing production processes and achieving superior quality in metalworking projects. With advanced features, cutting-edge technology, and a focus on precision, ACCURL’s bending equipment empowers businesses to meet even the most demanding industry standards. Whether you’re in automotive, construction, or aerospace, our solutions are tailored to elevate your operations.