Fabricating Aluminium Parts for Robotics

Table of Contents

- Introduction

- Why Aluminium is Ideal for Robotics

- Lightweight and Durable

- Corrosion Resistance

- Thermal Conductivity

- Flexibility in Design

- Applications of Aluminium in Robotics

- Structural Frames

- Robotic Arms

- Housings and Casings

- Gears and Components

- Techniques for Fabricating Aluminium Parts for Robotics

- CNC Machining

- Laser Cutting

- Welding and Joining

- Surface Finishing

- Challenges in Aluminium Fabrication for Robotics

- Precision Requirements

- Cost of Specialized Processes

- Material Limitations

- Why Choose Aluminium Fabrication in Chandigarh?

- Conclusion

- FAQs

Introduction

Aluminium plays a critical role in the robotics industry, thanks to its unique properties like lightweight strength, durability, and flexibility. From robotic arms to structural frames, aluminium ensures that robots are efficient and reliable in various industries. If you’re exploring opportunities for Aluminium Fabrication in Chandigarh, understanding the fabrication process and its benefits for robotics can lead to exceptional results in innovative projects.

Why Aluminium is Ideal for Robotics

Lightweight and Durable

Aluminium offers the perfect balance of weight and strength, reducing energy consumption and enhancing mobility in robotic systems.Corrosion Resistance

Its natural oxide layer prevents corrosion, ensuring long-lasting performance in diverse environments.Thermal Conductivity

Aluminium dissipates heat efficiently, making it ideal for components like heat sinks in robotic systems.Flexibility in Design

Aluminium is highly malleable, allowing intricate and precise designs essential for robotics.

Applications of Aluminium in Robotics

Structural Frames

Aluminium is widely used for building the skeleton of robots due to its strength and low weight.Robotic Arms

Its lightweight nature makes aluminium ideal for robotic arms, improving speed and precision.Housings and Casings

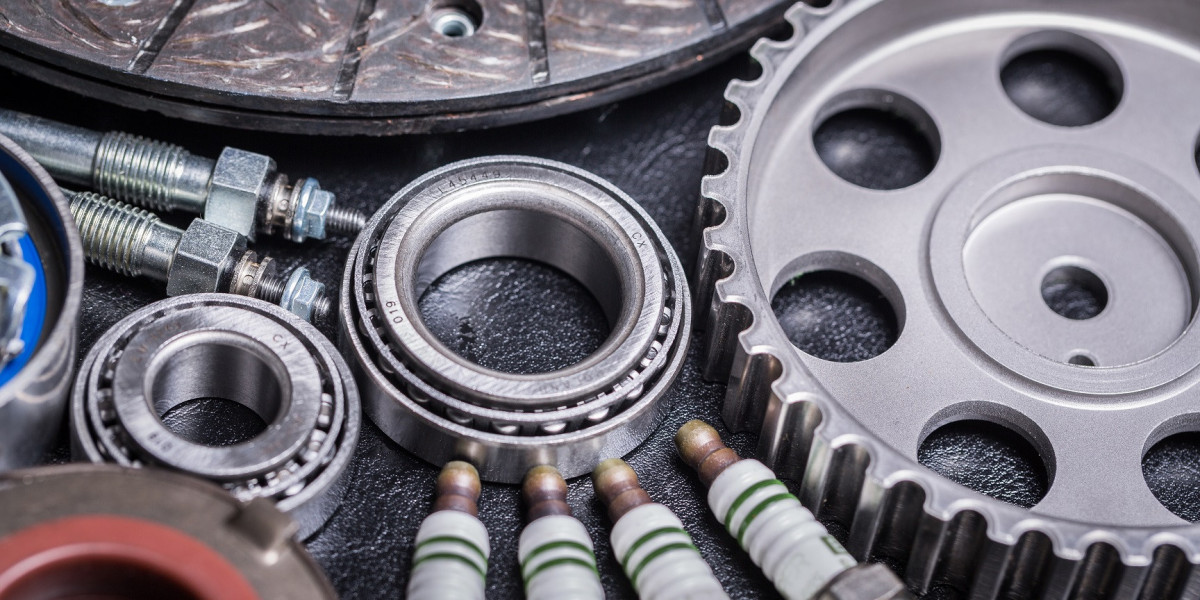

Aluminium housings protect sensitive robotic components from external factors like dust and heat.Gears and Components

Aluminium gears and joints reduce wear and tear while maintaining smooth movement.

Techniques for Fabricating Aluminium Parts for Robotics

CNC Machining

CNC machines ensure precision in creating complex parts with tight tolerances.Laser Cutting

Laser cutting allows accurate shaping of aluminium sheets for intricate designs.Welding and Joining

Advanced techniques like TIG welding are employed to create strong and seamless joints.Surface Finishing

Anodizing and powder coating improve the durability and aesthetics of aluminium components.

Challenges in Aluminium Fabrication for Robotics

Precision Requirements

Robotics demands highly accurate parts, which can be challenging to achieve without advanced tools.Cost of Specialized Processes

Processes like CNC machining and anodizing can increase production costs.Material Limitations

Despite its benefits, aluminium’s lower tensile strength compared to some alloys can pose challenges.

Why Choose Aluminium Fabrication in Chandigarh?

Chandigarh’s skilled fabricators and advanced facilities make it a hub for high-quality aluminium fabrication. Choosing Aluminium Fabrication in Chandigarh ensures precision, innovation, and cost-effective solutions tailored to the needs of robotics.

Conclusion

Aluminium fabrication for robotics enhances efficiency, durability, and design flexibility. From structural components to intricate robotic arms, aluminium offers endless possibilities for innovation. By partnering with the Best Aluminium Fabrication in Chandigarh, you can achieve exceptional results in your robotic projects with tailored solutions and unmatched expertise.

FAQs

Why is aluminium preferred for robotics?

Aluminium is lightweight, durable, and flexible, making it ideal for robotic applications.What fabrication techniques are used for aluminium robotic parts?

CNC machining, laser cutting, welding, and anodizing are commonly used techniques.Can aluminium components handle high temperatures in robotics?

Yes, aluminium’s thermal conductivity ensures efficient heat dissipation in robotic systems.What industries use aluminium robotics?

Aluminium robotics are used in industries like manufacturing, healthcare, and logistics.How can I find reliable aluminium fabricators for robotics?

Look for fabricators with advanced tools and expertise, like those offering Aluminium Fabrication in Chandigarh.Are aluminium robotic parts eco-friendly?

Yes, aluminium is 100% recyclable, making it an eco-friendly choice for robotics.Can aluminium parts handle high-precision tasks?

Yes, advanced machining techniques ensure aluminium parts meet precision requirements for robotics.What is the lifespan of aluminium components in robotics?

With proper care and design, aluminium components can last for decades in robotic systems.Why choose Aluminium Fabrication in Chandigarh for robotics?

Fabricators in Chandigarh provide cost-effective and innovative solutions for aluminium robotic parts.Can aluminium robotic parts be customized?

Yes, aluminium can be fabricated into customized shapes and designs for specific robotic applications.